Roofing System

Roofing System

Today, a wide range of membranes and flat roofing systems are available to protect homeowners’ investments. That’s why we strive to enlighten you so that you have the best possible option for your roofing.

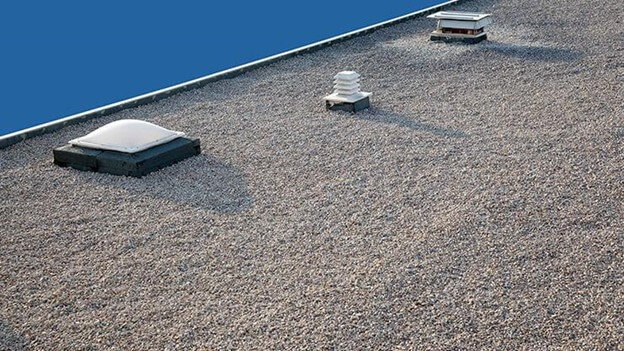

Multi-layer

Application: Given its weight, on a building where there was this system of covers. An evaluation by a structural engineer may be appropriate.

This system has already proven its effectiveness. Commonly referred to as ‘asphalt and gravel,’ this type of roofing generally consists of perforated bituminous felts or fiberglass felts alternated in hot asphalt The waterproofing complex is protected by the addition of gravel in hot bitumen.

Advantages: Cost, durability (20-25 years), wind resistance, easy maintenance.

Disadvantages: Weight, odor during application.

Elastomeric Membrane

The elastomeric membrane consists of membranes made of asphalt added with a styrene-butadiene-styrene (SBS) polymer and reinforced with a glass veil, non-woven polyester, or a composite reinforcement. Modified bitumen membranes are installed in two layers, and the top layer is covered with granules.

Advantages: Durability (25-30 years), low maintenance.

Disadvantages: Cost, professional maintenance required, monitor for water accumulations.

Rubberized bitumen waterproofing system applied hot.

These membranes are only used for inverted system specifications.

Typically used in waterproofing projects, hot-applied rubberized bitumen membranes are installed directly on the concrete deck and under the insulation. The system is usually protected by a gravel ballast, patio tiles, a rooftop terrace, and/or a green roof.

Advantages: Wind resistant, durability (25-30 years), low maintenance

Disadvantages: More complicated visual inspections and repairs, weight of the ballast, the structure must be evaluated by an expert.

PVC Membrane

Advantages: Durability, fire protection, cold and clean installation

Disadvantages: Single-layer system, thermographic inspection required to detect leaks.

TPO Membrane

Advantages: Cost-effective, low thermal radiation and high reflectivity

Disadvantages: Single-layer system, thermographic inspection required to detect leaks.

EPDM Membrane

Advantages: Cost-effective

Disadvantages: Single-layer system, thermographic inspection required to detect leaks.